Table of Contents

Logistics Cost: A Comprehensive Guide for Businesses

In a rush and need the TL/DR version?

This article provides a detailed overview of logistics costs, emphasizing their significant impact on business operations and profitability. It explores key cost components, offers strategies for optimization, and highlights the importance of effective logistics management.

Key Pointers:

-

Logistics Costs Breakdown: Includes transportation, warehousing, inventory holding, packaging, order fulfillment, and reverse logistics.

-

Impact on Profitability: Poor logistics cost management can reduce profit margins and harm customer satisfaction.

-

Cost-reduction strategies include Optimizing transportation routes, consolidating shipments, negotiating better rates, and using automation to reduce costs.

-

Key Metrics: Track KPIs such as transportation cost per unit, warehouse utilization, and inventory turnover to improve cost visibility.

-

Outsourcing: Third-party logistics (3PL) can reduce overhead and improve operational efficiency.

Effectively managing logistics costs is essential for maintaining a competitive edge and ensuring operational success. Businesses can significantly reduce costs by employing strategic optimization techniques and leveraging technology.

Note: While this summary captures highlights, it might miss some finer points—reading the full article is encouraged.

Introduction

Logistics cost is a pivotal factor that defines a company's operational efficiency and profitability. As logistics processes can account for up to 25-45% of total operational expenses, businesses must pay close attention to these costs to remain competitive. Effective logistics cost management involves understanding, measuring, and optimizing expenses across transportation, warehousing, inventory, and order fulfillment. With the global logistics market projected to exceed USD 14 trillion by 2028, understanding logistics costs is more important than ever to maintain a strong foothold in this dynamic industry.

Key Highlights about Logistics Costs:

-

Overall logistics costs encompass all expenses related to the movement, storage, and management of goods within a supply chain.

-

Poor logistics cost management can significantly impact profit margins and customer satisfaction.

-

Businesses can reduce total logistics costs by optimizing transportation routes, streamlining warehouse operations, and improving inventory management.

-

Measuring logistics costs with the right KPIs and benchmarks provides actionable insights for cost optimization.

What Are Logistics Costs?

Logistics costs refer to the total expenses incurred in moving goods from their point of origin to the end consumer. These costs encompass transportation, warehousing, inventory holding, order processing, and other administrative expenses tied to supply chain operations. For businesses, logistics processes cost is not just limited to their operating costs. They are a crucial determinant of overall profitability, business performance, and customer satisfaction. Efficiently managing these costs can directly enhance a company’s competitive edge.

Key Components of Logistics Costs:

-

Transportation Costs: Total transportation costs related to freight (the cost of trucking companies), fuel surcharges, and handling fees are called shipping costs. They also include vehicle maintenance costs and shipping carriers' costs.

-

Warehousing Fees: Total logistics costs for storage facilities (like warehouse space), utilities, and security, including equipment costs and logistics operations costs. It also includes the cost of leasing and purchasing land.

-

Inventory Carrying Costs: It covers capital tied up in storing inventory, including inventory depreciation and insurance (especially in the case of perishable goods).

-

Packaging and Handling: It involves the operational costs associated with materials and labor for secure shipping.

-

Reverse Logistics Costs: Expenses for managing returns and damaged goods.

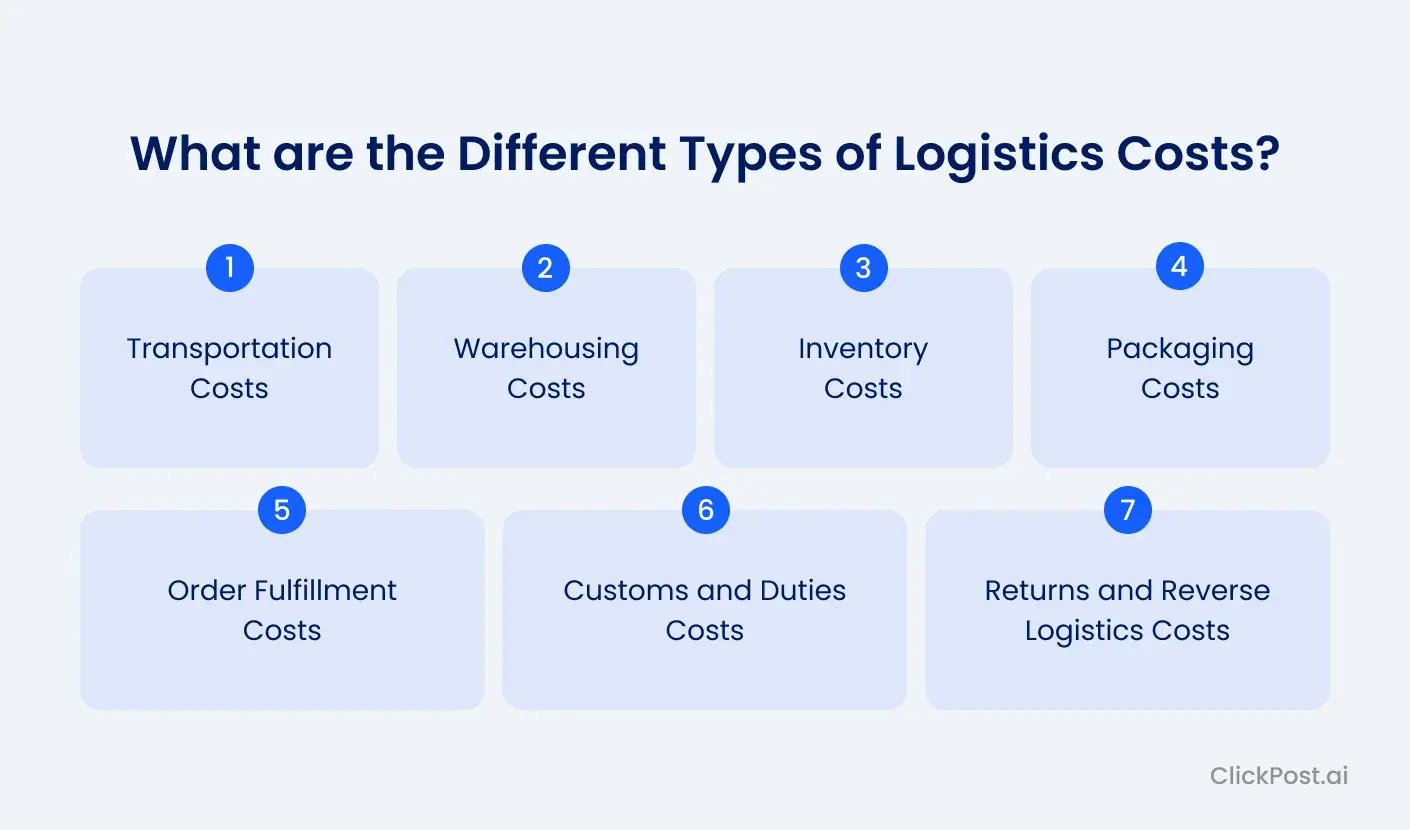

What are the Different Types of Logistics Costs?

It is vital to understand the various parts that comprise the cost of logistics.

Let us explore the various parts that make up the cost of logistics.

1. Transportation Costs

Transportation costs form the backbone of logistics expenses, covering everything from fuel charges to carrier fees for air, sea, and road freight. These costs vary depending on factors such as shipment distance, mode of transport, and fuel price fluctuations. Optimizing transportation routes and consolidating shipments can significantly reduce these costs, ensuring efficiency without compromising delivery timelines.

2. Warehousing Costs

Warehousing costs encompass the expenses of storing goods in facilities, including rent, utilities, and equipment. Businesses also incur additional costs for security, inventory monitoring, multiple warehouses, and damage control. Efficient warehouse space layouts and automated processes can minimize these expenses while ensuring timely order fulfillment.

3. Inventory Costs

Inventory costs account for the capital tied up in holding stock, including storage insurance, taxes, and depreciation. High inventory-carrying costs can erode profitability, making inventory management a critical focus area. Businesses can reduce these costs through demand forecasting and implementing just-in-time inventory strategies.

4. Packaging Costs

Packaging costs involve materials, labor, and technology used to securely pack goods for transport. Custom packaging solutions and bulk procurement of materials can help lower costs without compromising product safety or brand presentation.

5. Order Fulfillment Costs

Order fulfillment costs include picking, packing, and shipping orders. These costs directly affect customer satisfaction and operational efficiency. Streamlining order processing with technology and optimizing workflows can enhance fulfillment efficiency while reducing expenses.

6. Customs and Duties Costs

Customs and duties costs are a significant expense for businesses involved in international trade. These costs cover tariffs, taxes, and regulatory compliance for importing or exporting goods. Partnering with experienced customs brokers can ensure smooth operations and minimize delays.

7. Returns and Reverse Logistics Costs

Reverse logistics costs arise from managing returned goods, defective items, or unsold inventory. Efficient return policies, streamlined processing, and effective recycling strategies can reduce these costs while maintaining customer satisfaction.

How to Measure Logistics Costs

Measuring logistics costs is essential to understanding operational inefficiencies and identifying cost-saving opportunities. By focusing on key performance indicators (KPIs) and analyzing expenditures across the supply chain, businesses can gain actionable insights.

Key Considerations for Measuring Logistics Costs:

-

Establish Relevant KPIs: Metrics such as transportation cost per unit, warehouse utilization rate, and inventory turnover rate provide clarity on expenses.

-

Gather Comprehensive Data: Collect accurate data from all logistics functions, including procurement, warehousing, and transportation.

-

Analyze Direct and Indirect Costs: Differentiate between costs like freight charges (direct) and software subscriptions (indirect).

-

Benchmark Against Industry Standards: Compare performance metrics with competitors or historical data to identify potential areas of improvement.

-

Leverage Technology: Use analytics tools and logistics management software for real-time insights and better cost visibility.

9 Tips to Reduce Logistics Costs

Reducing logistics costs is not just about saving money—it’s about improving operational efficiency, enhancing customer experience, and staying competitive in industries like eCommerce, retail, and manufacturing.

With logistics costs accounting for a significant share of business expenses, companies need to adopt strategic approaches to minimize waste and maximize value. Here are nine actionable tips to help you reduce logistics costs effectively.

1. Optimize Transportation Routes

Optimizing transportation routes ensures that shipments follow the most efficient paths, reducing travel time and fuel consumption. Advanced route optimization software can analyze traffic patterns, delivery locations, and fuel costs to determine the best routes for deliveries. For businesses managing large fleets, this can lead to significant cost savings.

Key Steps to Consider:

-

Use GPS-enabled route planning tools for real-time adjustments.

-

Monitor road conditions and weather forecasts to avoid delays.

-

Schedule deliveries during off-peak hours to minimize traffic disruptions.

2. Consolidate Shipments

Consolidating shipments involves combining multiple orders into a single load, maximizing the use of transport capacity, and reducing the number of trips. This practice is particularly effective for businesses with high shipment volumes or those delivering to nearby destinations.

Key Steps to Consider:

-

Group shipments geographically to avoid unnecessary detours.

-

Partner with carriers offering consolidation services. You can also reach out to freight brokers for this.

-

Invest in technology to streamline order batching and coordination.

3. Negotiate Carrier Rates

Building strong relationships with logistics providers can help businesses negotiate better shipping rates and service agreements. Carriers often offer volume-based discounts, flexible terms, or exclusive perks to long-term clients.

Key Steps to Consider:

-

Regularly review carrier contracts to ensure competitive pricing.

-

Leverage your shipment volume to negotiate bulk discounts.

-

Compare rates across multiple carriers for similar routes and services.

4. Automate Processes

Automation is a game-changer in logistics, enabling businesses to reduce manual errors, speed up processes, and improve cost efficiency. From order processing to warehouse management, automation can simplify operations and reduce labor costs.

Key Steps to Consider:

-

Implement warehouse management systems (WMS) for efficient inventory handling.

-

Use automated sorting and packing machines to save time.

-

Integrate order processing tools for seamless data synchronization.

5. Use Multi-Modal Shipping

Multi-modal shipping combines different transportation modes—such as rail, road, and sea—to optimize costs and delivery timelines. This approach offers flexibility and cost savings for long-distance or international shipments.

Key Steps to Consider:

-

Analyze shipment requirements to determine the best transport mix.

-

Partner with logistics providers specializing in multi-modal solutions.

-

Utilize containerized transport to simplify transfers between modes.

6. Outsource to Third-Party Logistics (3PL) Providers

Outsourcing logistics to 3PL providers allows businesses to leverage expert services without incurring the costs of in-house operations. These providers offer end-to-end solutions, from transportation and warehousing to inventory management.

Key Steps to Consider:

-

Evaluate the cost-benefit ratio of outsourcing versus in-house logistics.

-

Choose a 3PL partner with a proven track record in your industry.

-

Monitor 3PL performance through service-level agreements (SLAs).

7. Reduce Returns and Reverse Logistics Costs

Returns and reverse logistics can be costly if not managed effectively. Streamlining return policies and processes can minimize expenses while maintaining customer satisfaction.

Key Steps to Consider:

-

Offer clear product descriptions to reduce return rates.

-

Use automation for faster return processing.

-

Partner with carriers offering cost-effective reverse logistics services.

8. Use Technology for Real-Time Tracking

Real-time tracking provides visibility into shipments, enabling businesses to anticipate delays, optimize resources, and improve decision-making. Advanced tracking systems can also enhance customer satisfaction by providing timely updates.

Key Steps to Consider:

-

Invest in IoT-enabled tracking devices for accurate location updates.

-

Use dashboards for centralized monitoring of shipments.

-

Share tracking information with customers for transparency.

9. Optimize Labor Costs

Labor is a significant cost driver in logistics. Optimizing labor allocation and productivity can significantly reduce expenses while ensuring high operational efficiency.

Key Steps to Consider:

-

Cross-train employees to handle multiple roles during peak periods.

-

Implement performance-based incentives to boost productivity.

-

Use workforce management tools to streamline scheduling and resource allocation.

Reduce Your Logistics Costs with ClickPost – Get Started Today!

Managing logistics costs has never been easier than with ClickPost, a leading logistics management platform designed to optimize your operations and improve cost efficiency. With ClickPost, businesses can enjoy streamlined workflows, real-time insights, and unmatched flexibility.

Key Features of ClickPost:

-

Multi-Carrier Integration: Seamlessly connect with top carriers for diverse shipping needs.

-

AI-Driven Route Optimization: Minimize fuel consumption and transit times with intelligent route planning.

-

Automated Reverse Logistics: Simplify returns processing to save time and reduce costs.

-

Centralized Tracking: Monitor all shipments in real time from a single dashboard.

Transform your logistics strategy today with ClickPost. Book a demo and start saving!

Conclusion

Logistics costs are an inevitable part of any supply chain, but their effective management can make a significant difference to your bottom line. By adopting strategies like route optimization, automation, and leveraging technology, businesses can not only reduce expenses but also enhance operational efficiency and customer satisfaction.

As the logistics landscape continues to evolve, staying proactive and innovative is key. Platforms like ClickPost provide businesses with the tools and insights needed to navigate challenges and capitalize on opportunities, ensuring long-term success in a competitive market.

FAQ's

1. What are the main components of logistics costs?

Logistics costs include transportation, warehousing, inventory holding, packaging, order processing, and reverse logistics expenses. Each component contributes to the overall efficiency of a supply chain.

2. What factors contribute to high logistics costs in eCommerce?

Key factors include inefficient transportation routes, high return rates, a lack of automation, and insufficient inventory management. Rising fuel prices and labor costs also contribute.

3. How does shipping volume affect logistics cost efficiency?

Higher shipping volumes often lead to better-negotiated rates with carriers and improved load optimization, reducing per-unit transportation costs.

4. What role does technology play in reducing logistics costs?

Technology streamlines processes, enhances visibility and improves decision-making through tools like route optimization, real-time tracking, and automated inventory management.

5. What are the most effective strategies for managing reverse logistics costs?

To manage reverse logistics costs, businesses can adopt efficient return policies, automate return processing, and partner with logistics providers specializing in cost-effective reverse logistics solutions.